- #Xbar r chart minitab software

- #Xbar r chart minitab free

Create a XbarR Chart in Excel using QI Macros. Minitab 17 went back to Rbar/d2 and Sbar/c4 for XbarR/S control limits, but retained pooled stdev for Cp/Cpk calculations when using multiple samples. Donald Wheeler in Advanced Topics in Statistical Process Control says: "Even though the Pooled estimator is common in many applications, the robustness of Rbar/d2 and Sbar/c4 makes them the preferred estimators for use with process behavior charts."įurthermore, Minitab started using Pooled Standard Deviation to calculate Cp/Cpk, and control limits on XbarR and XbarS Charts in versions 15 and 16. The answer is that they use a different estimator. Note: Some people wonder why QI Macros results are a tiny bit different from some versions of other software.

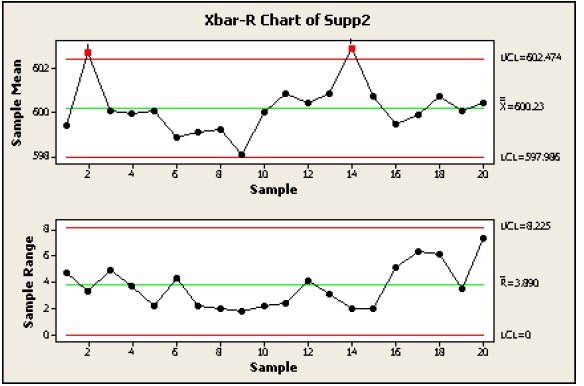

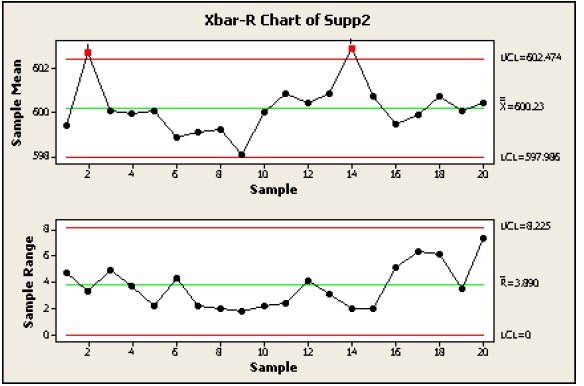

If the Range Chart looks okay, then calculate, plot, and evaluate the X Chart. If it is "out of control," so is the process. Process: Calculate, plot, and evaluate the Range Chart first. * "Introduction to Statistical Quality Control," Douglas C. K = number of subgroups ( a group of measurements produced under the same set of conditions)Ī 2, D 3 and D 4 are constants based on n

#Xbar r chart minitab free

Free Agile Lean Six Sigma Trainer Training. Animated Lean Six Sigma Video Tutorials. Then go to “Stages” in I Chart or any Chart Options and in the ” Define stages(historical groups) within this variable” choose column A. This can be done by defining the months in the first column and actuals in the second column. Moreoever you can also see pre and post improvement in the control limits and mean in the same chart also. However they dont call it as control limits but standard deviation limit bounds. If you just enter 2 it will show control limits at 2 stdevs.You can even enter 2.2 etc.Īnd there is an option below that to enter the control limits itself!!! If you enter 1,2,3 then it will shown three control limits like region a,b,c. In S Limits tab you can either define at how many stdev you want the control limits to be shown 1,2,3 In Parameters you can define Mean and Stdev( Historical) It is possible in Minitab to fix control limits and mean even in minitab 14. Let me provide my penny’s worth comments. I hope this helps to answer your question. You will find out for sure after about 100 points or so. Minitab give no capability to lock means and control limits to allow control charting in this manner, so I have shifted control charting efforts to Excel until Minitab fixes that issue.įinally, your 25 subgroups of 5 samples is adequate for you to establish control limits and to determine the stability of your process in the short term. In fact in one quote Shewhart said “control limits should be adjusted if and only if a point plots outside a control limit”. Shewhart describes control charts with fixed means, UCLs, and LCLs, after the limits are established and says that control limits should only be adjusted when the chart gives positive indication of an out of control indication. This can cause you to miss indications of out of control conditions. One thing to be aware of when using Minitab for control charting is that the control limits and mean are continuously updated in Minitab.

What this means is if your mean shifts by 0.5 sigma, you have >99% probability that you will get an out of control indication (exceeding control limit) within 10 points.Īrguably, if your chart shows no out of control points in 25 plotted points, you can be relatively confident that you mean has not shifted more than 4% (0.25 sigma). I have done some probability calculations concerning this subject and I have arguably determined that if you get a sudden mean shift, the probability that the first point you plot following the mean shift exceeds a control limit (UCL or LCL) is: However, if I understand your question, you are really asking what the probability of detection of a mean shift is for an X-bar, R chart.

#Xbar r chart minitab software

Does any software (like Minitab) compute and report the beta risk along with creating the Xbar chart?Īs Helper pointed out, control charting is not hypothesis testing. Is there an equation to compute beta risk for an Xbar chart?ħ. What is the probability of this happening (beta risk)?Ħ. I recognize the possibility that the process center could have changed during this period of time (1 hour interval), but don’t know the probability of NOT DETECTING such a change because of random sampling error.ĥ. Both points are in within the statistical control limits, as are all of the other subgroup averages.Ĥ. What is the beta risk for this situation?Ī simple example will clarify what I mean by this.ģ. All points pass the various zone tests offered in Minitab All points are within the statistical control limitsħ. The control charts are made using Minitab softwareĦ. Samples are taken every hour during each of 2 shifts.ĥ. I have a perplexing question regarding the use of an Xbar chart.Ĥ.

0 kommentar(er)

0 kommentar(er)